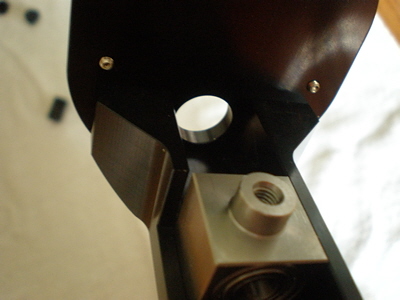

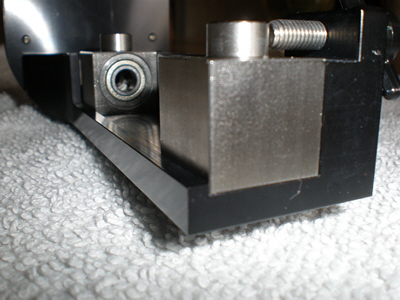

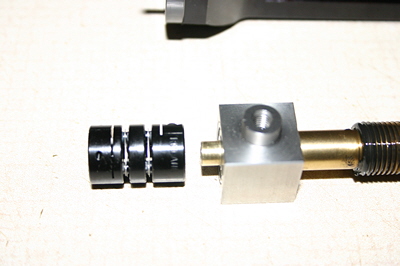

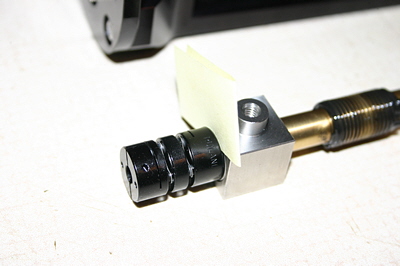

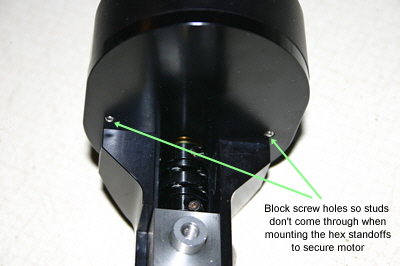

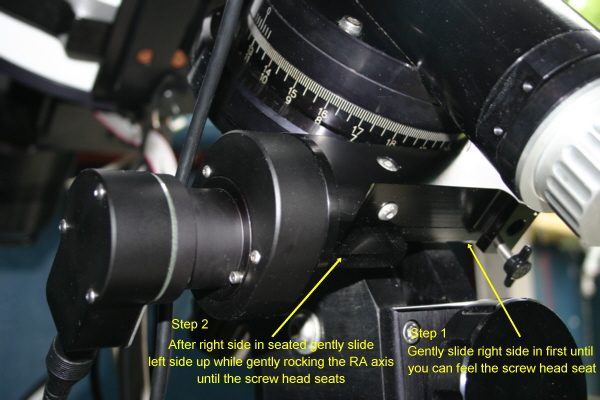

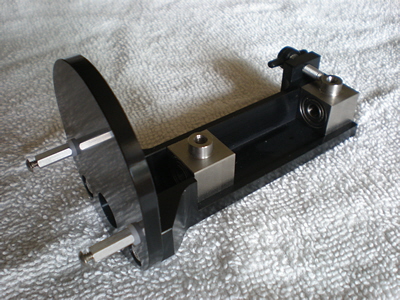

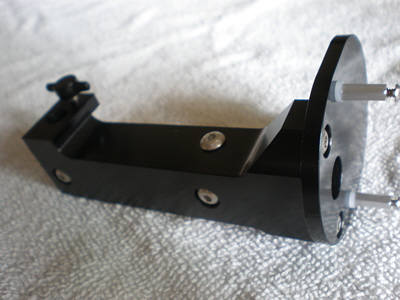

Below are images and assembly steps of the new Losmandy G11 one piece worm block I received June 11, 2010. This design looks to

address the issue of having the worm blocks parallel (supposedly the cause of the 76 second error) and also to make the motor/gear unit part of the worm platform.

>

>